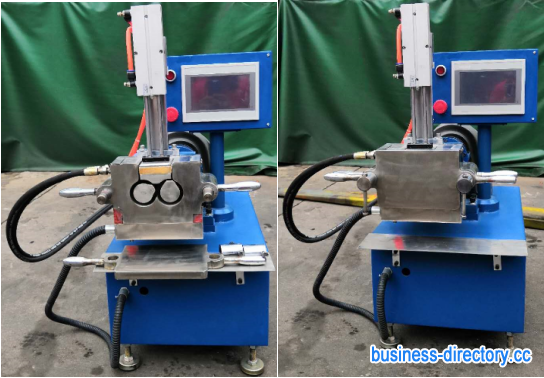

Brand:Zhenggong

1. Volume of mixer: 0.1L

2. Main motor: AC motor, power 1,5 kW

3. Reducer: The base and frame are welded with low carbon steel and contain forced lubrication cycle system.

4. Rotor: Double-edged and synchronous rotor structure (also designed and manufactured according to the rotor structure diagram provided by users). Specific parameters of the front and rear rotor speed ratio of 1:1.20 or St synchronous rotor can be customized free of charge according to customer needs. Cast steel quenching and hardening treatment, hard chromium plating on the surface; Bearing is ball-shaft roller bearing lubricating oil bath; Rotor speed is the highest: 0.1l:36 RPM specific speed can be customized free of charge according to customer needs

5. Surface wall: steel structure, drilling heating, hardening and hard chromium plating on the inner surface;

6. Bracket: steel structure, hardened inner surface with hard chromium plating;

7. Top bolt: cylinder driven, hard chromium plated surface

8. End seal: high wear-resistant material for sealing ring, self-lubricating bearing, hinge spring top-pressing seal

9. Feeding hopper: manual operation

10. Control mode: operation separately manual and semi-automatic;

Maximum temperature of internal mixer: Standard internal mixer is from room temperature to high temperature internal mixer has done 650 C a 300 C.

Mechanical main body

11. The base frame is welded with profiled steel and steel plate and made by processing.

12. The middle trough of mixing room is made of wear-resistant alloy steel.

Side wall is welded and processed with medium carbon steel plate.

13. Alloy steel is used for the axis and blade of stirring shaft

14. Bearing seats are made of zg20 steel and bearings are made of roller bearings.

15. Feeding device This machine is designed as front feeding device. The pressure can be adjusted arbitrarily according to the air valve designated by the user.

16. The side end of the mixing shaft of the leak-proof device is tightened by mechanical shaft seal. The leak-proof structure has won the national patent.

Pressurizing cover device

17. Made of alloy steel for pressure cap, pressure is applied on the raw material during mixing operation, and air cylinder is used for vertical ascending and descending action.

Unloading device

18. Opening and closing unloading of structural mixing chamber

19. Discharge mode: Side plate, mixer W groove can be opened flexibly to complete quick 1 minute disassembly.

20. Unloading Power: Cylinder Driven or Manual

Transmission structure

21. The 1.5kW voltage of the main motor is 440V AC 220V 110V, and 400V P 380V can be chosen at will according to the customer's demand.

22. The main motor and reducer are connected in transmission mode.

piping

23. Air pressure piping, compressed air fittings (three-point combination, solenoid valve) and mechanical body piping

Main electrical control equipment

24. Temperature setting: automatic and manual

25. There are prompt actions, various time settings, alarms; can achieve positive and negative.

Advantage of machine platform

26. The main electrical parts are imported brands, and the whole machine bearings are made of American Timken TWB brand.

27. The stirring shaft is made of alloy steel wear-prone parts and welded with wear-resistant front steel imported from West Germany, which is tighter and more durable.

28. Mixing trough "mountain" type, the main body of mixing trough is made of wear-resistant alloy steel, and the shear part is surfacing welded with Xidefeng steel.

29. Side wall leak-proof device uses high-tech materials: leak-proof structure won national patent

30. Pressure cover adopts "M" structure to make the mixture more uniform and thorough.

31. Volume: 500 * 400 * 580 mm (W x D x H)

32. weight: 48kg

Contact:

TEL: (+86) 153 8283-6112 Email: brotherc@163.com

Contact:

TEL: (+86) 153 8283-6112 Email: brotherc@163.com